Silkscreen printing

Along with litho printing, silkscreen printing is among the techniques known as “planographic printing”, descended from lithography.

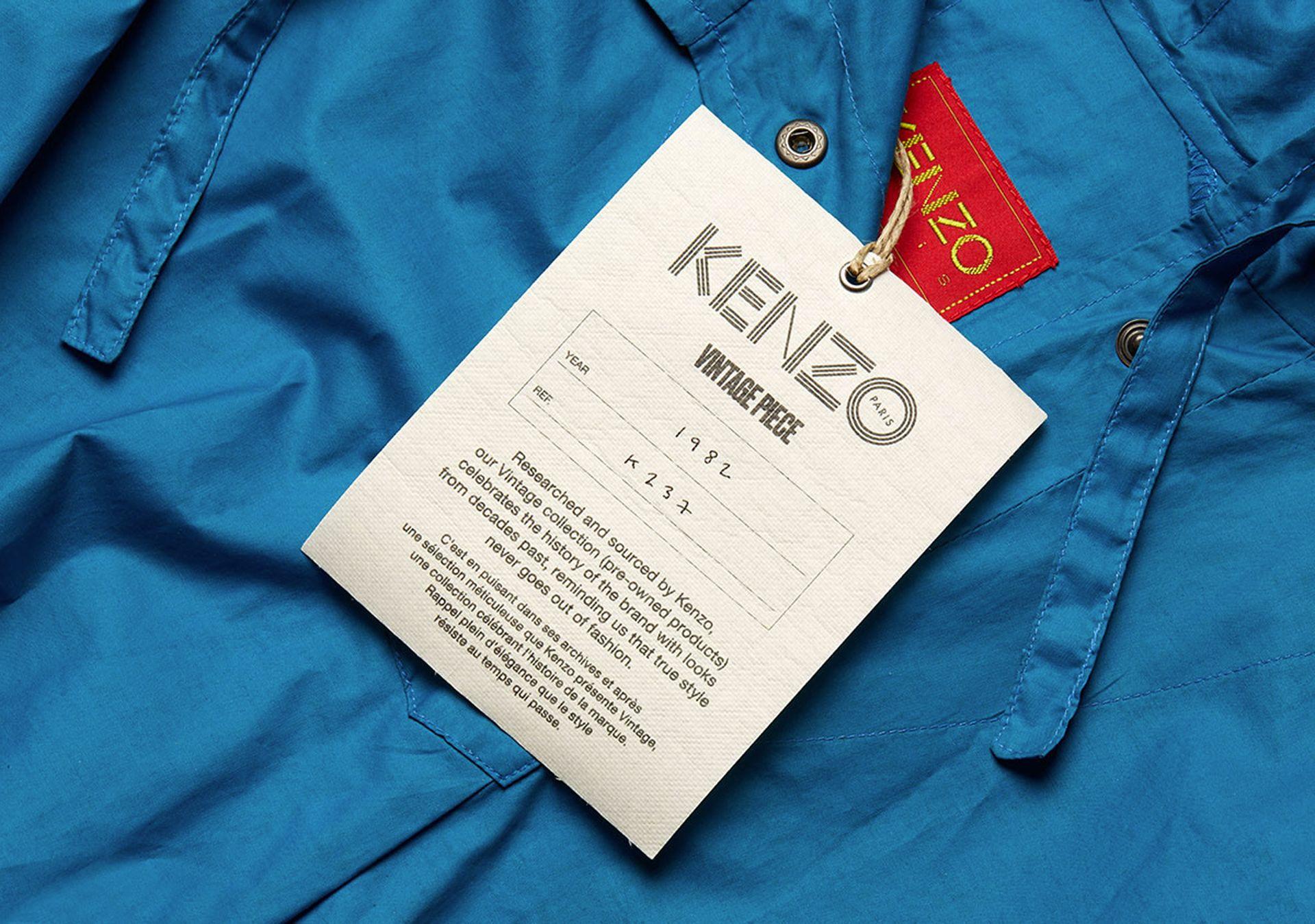

Invented in China during the Song Dynasty (960-1279), it has a rich history both in industry and in the arts, and today it continues to thrive as one of the most creative printing techniques. This is no doubt because of the fact that it offers a wide range of applications on large print volumes.

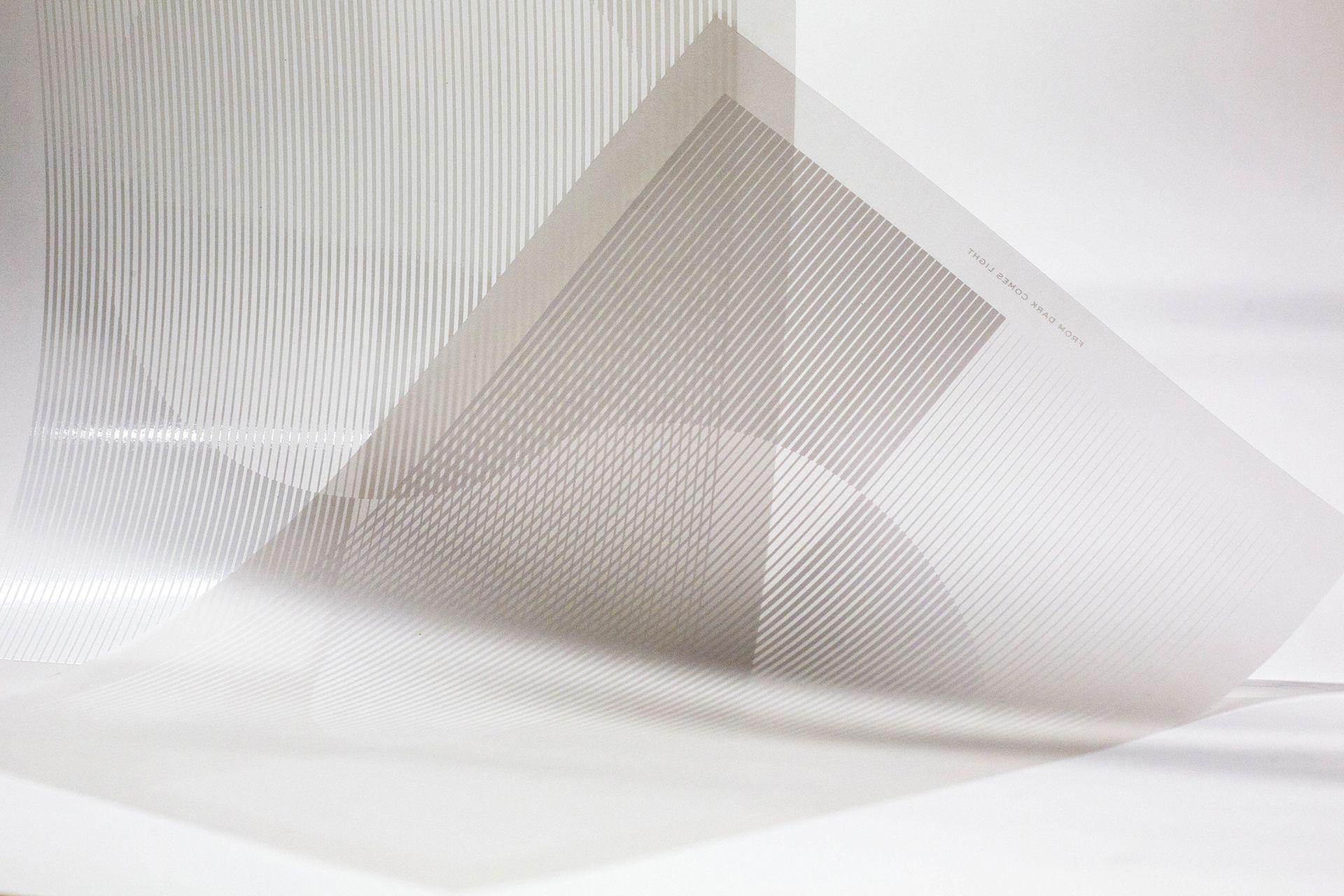

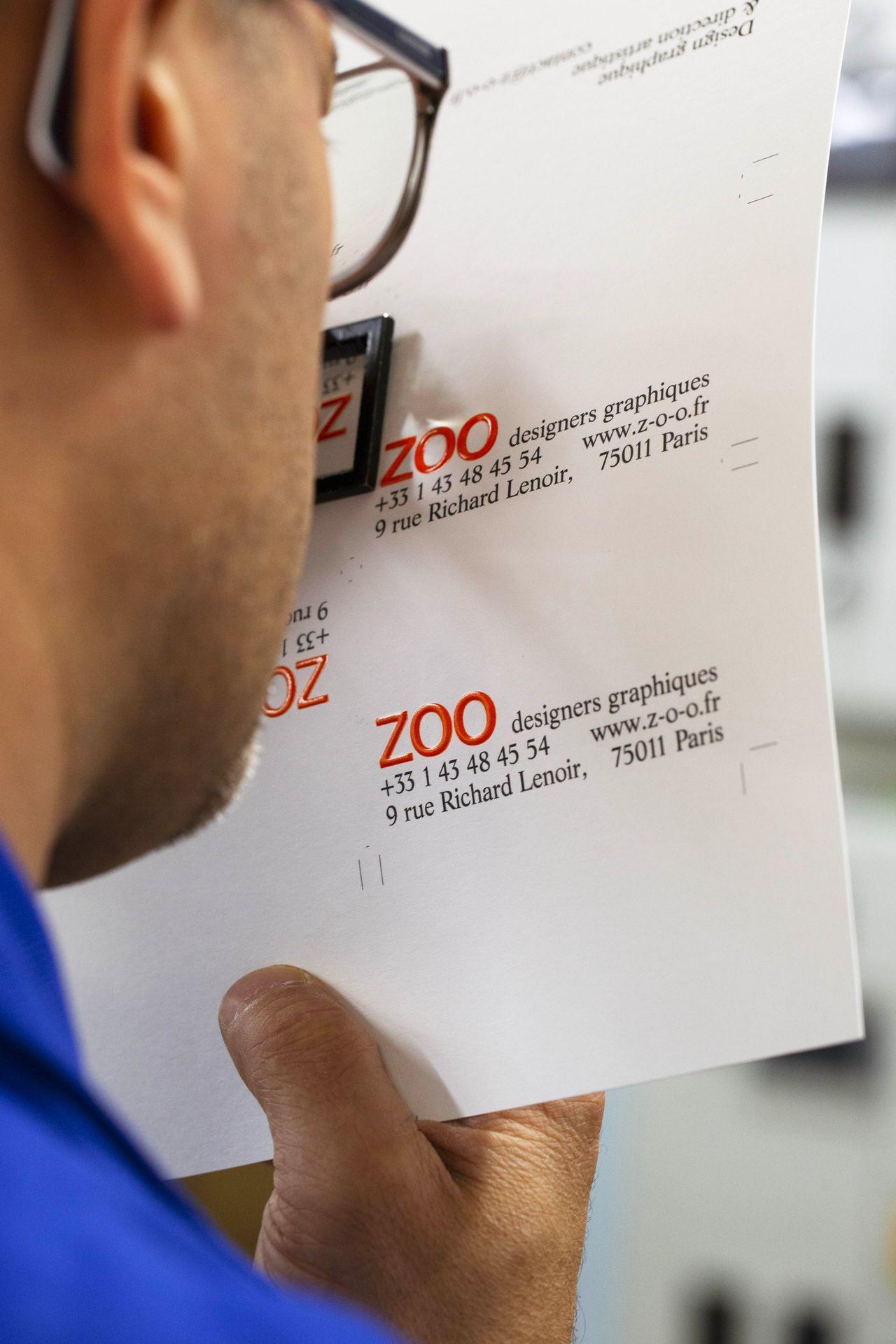

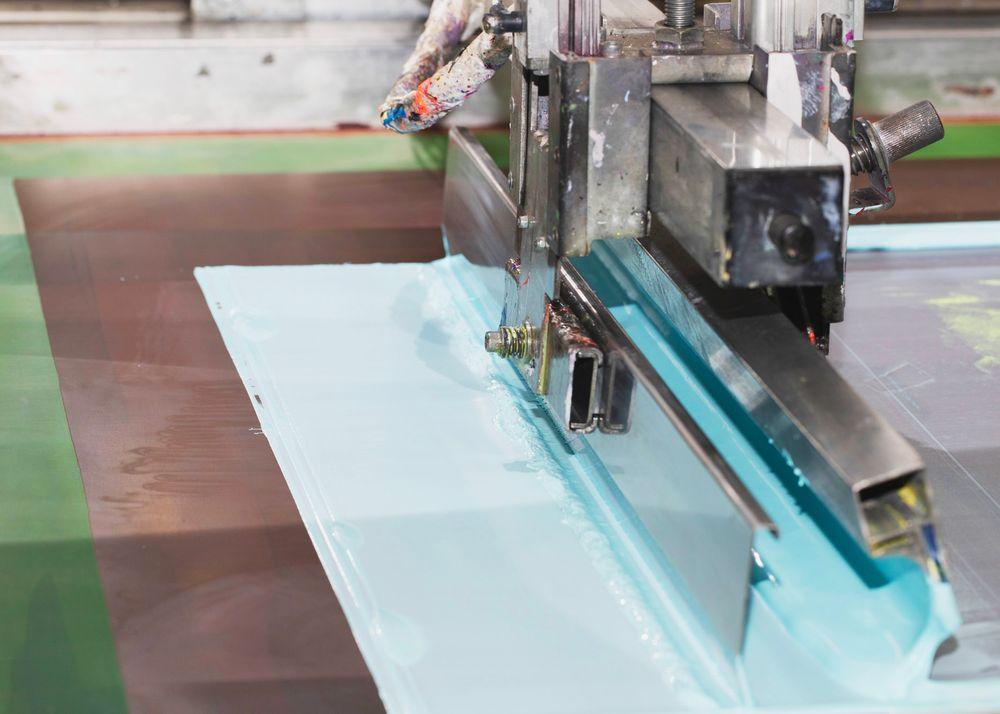

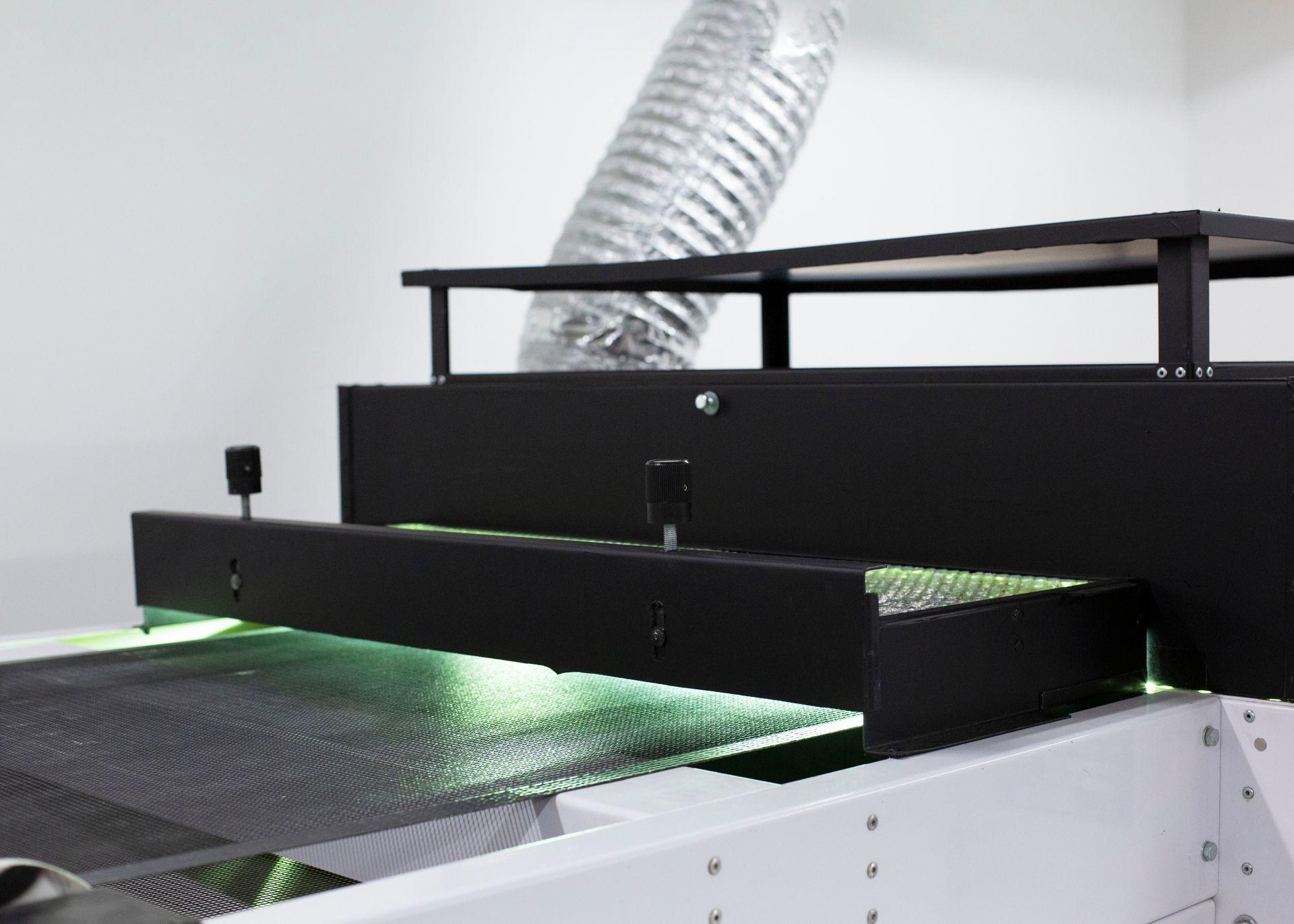

In our dedicated workshop, everything begins as it does in a photographic studio: by passing through the hermetic, mysterious murk of a darkroom. This is where our artisan silkscreen printer attentively prepares his tools, made up of screens stretched onto frames. These were originally made with silk and wood; today they are nylon and aluminium. The blank fabric is then prepared for printing after having been coated. Some say it is “flashed” when speaking of this phase of “photoscreening” the print film onto the tool. This way, one obtains a silkscreen printing tool that is nothing but a more sophisticated version of the principle of the stencil. Its screen weft and coating thickness offer multiple variations and possibilities.

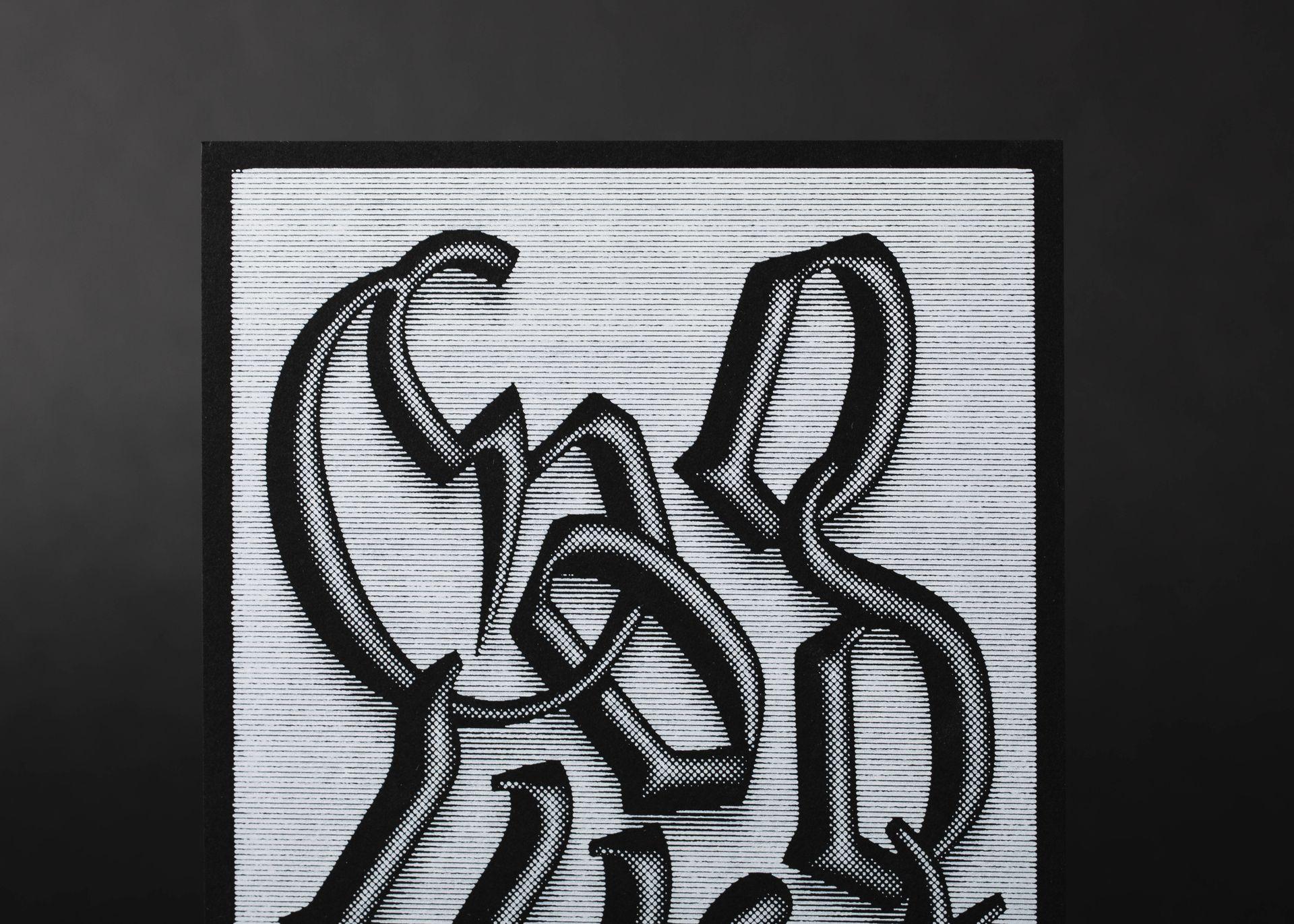

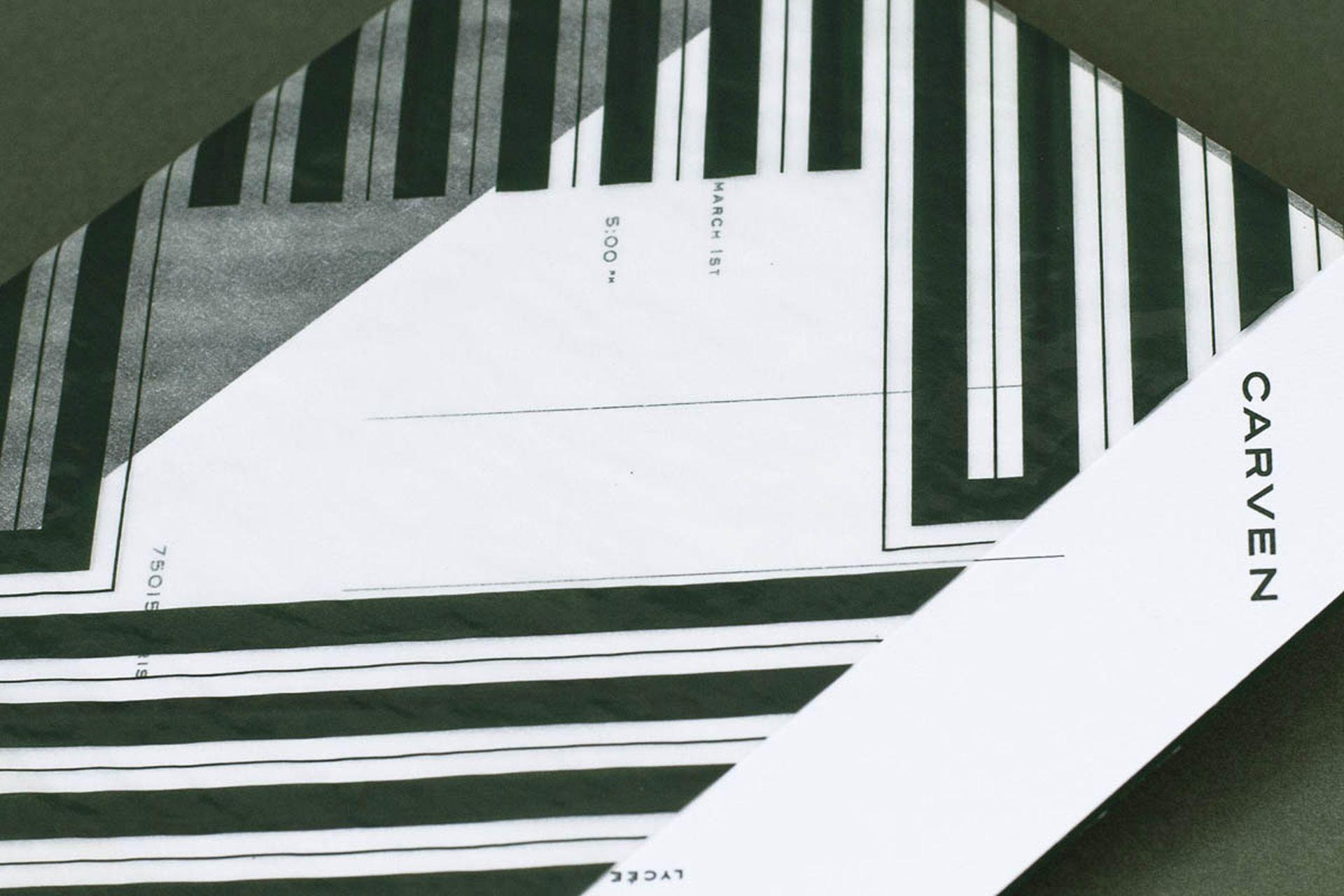

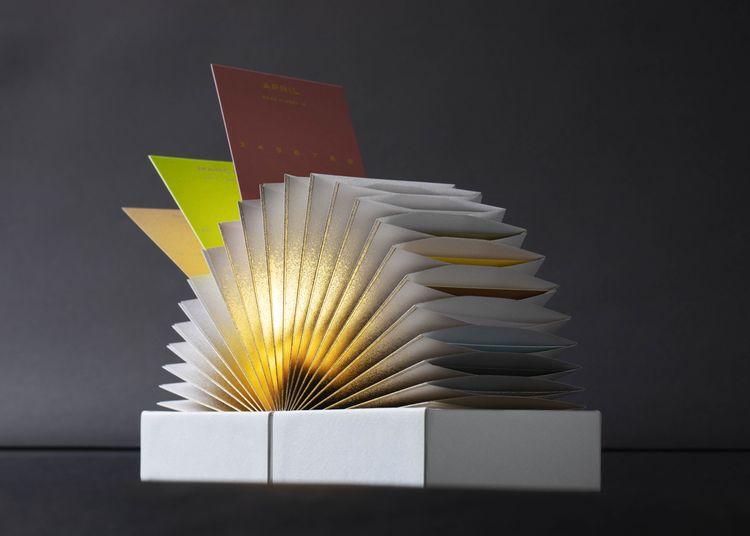

One finds just as many possibilities in the printing process itself. The ink is placed on the screen fabric and flatly applied with the help of a flexible squeegee. The operation is repeated as many times as the number of mediums and colours to print, with meticulous cleaning between each colour. Sheetfed printing also lends itself to experimentation with random applications. Starting from one same design, we can achieve varied renderings through additions or subtractions of ink, from stratum to stratum and directly. Each print then becomes unique.

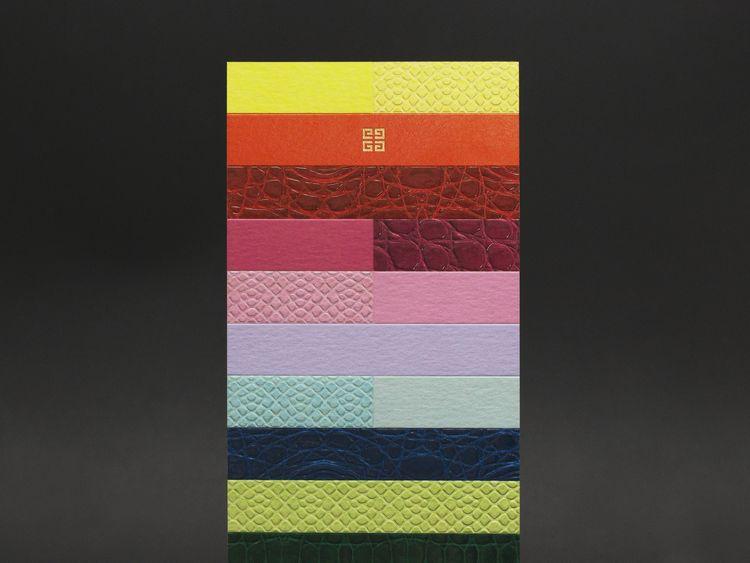

Furthermore, when it is treated with UV, the drying of the silkscreen prints enables very fine details to be obtained, thanks to the use of appropriate inks whose finishes our artisan completes by hand. This results in truly personalised recipes that make it possible to play with endless variations, combinations and superimpositions of colours and textures, creating nuanced relief, metallic, lacquered, matt, iridescent, glittery, gradient, phosphorescent, or “scratch-card” effects.

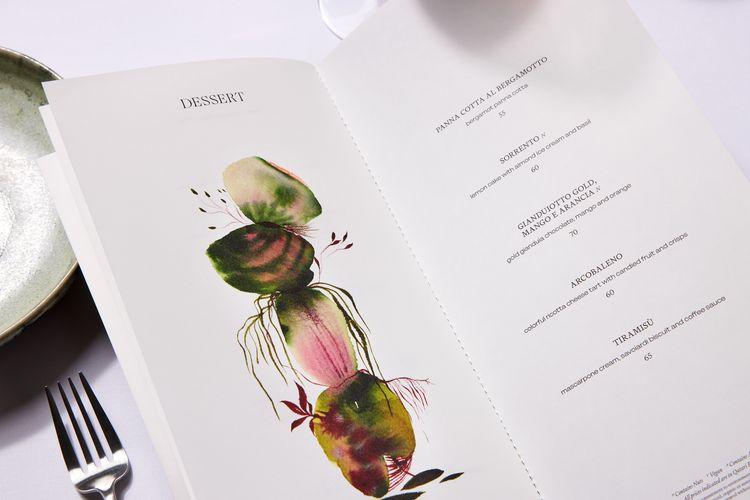

In addition to its extensive creative potential, silkscreen printing is also the ally of innovative explorations in terms of responsible printing. Because of the high ink density it is capable of achieving, it can be applied to a very wide range of mediums, particularly those in our library of eco-designed, sustainable materials. In the context of our own research and development, we also like to promote the uses of vegetable inks. Although they are often excluded from briefs because of their fragility, they are actually more resistant than they might seem.

"The inks are hand-finished by our silkscreen printer. Those personalised recipes make it possible to play with endless variations, combinations, and superimpositions of colours and textures."